Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsWhat is a Vial Filling and Sealing Machine and Its Role in Efficient Production

In the rapidly evolving pharmaceutical and biopharmaceutical sectors, ensuring efficiency in production processes is paramount. Among the critical components of filling and packaging operations, the "Vial Filling and Sealing Machine" plays an indispensable role. According to a recent report by MarketsandMarkets, the global market for vial filling and sealing equipment is projected to grow at a CAGR of 6.5%, reaching approximately $1.2 billion by 2026. This growth is driven by increasing demand for injectable drugs, enhanced focus on quality control, and the need for automation in manufacturing processes. The utilization of advanced vial filling and sealing machines not only optimizes production efficiency but also ensures the integrity and sterility of pharmaceutical products, thereby meeting international regulatory standards. As manufacturers strive for competitive advantage, investment in state-of-the-art vial filling and sealing technology represents a strategic move to enhance operational capabilities and improve output quality.

What is a Vial Filling and Sealing Machine: A Comprehensive Overview of Its Functionality

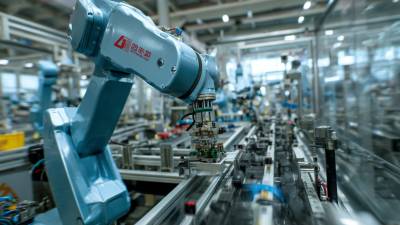

A vial filling and sealing machine is an essential piece of equipment used in various industries, particularly pharmaceuticals and biotechnology. This machine automates the process of filling vials with liquids, such as vaccines, medications, and serums, ensuring precision and reducing human error. The machine typically integrates several functions: it fills the vials to a predetermined volume, seals them with caps or stoppers, and often labels the final product. This comprehensive functionality boosts production efficiency by minimizing the time and labor required compared to manual processes.

The role of a vial filling and sealing machine extends beyond mere filling; it enhances product integrity and safety. By automating the sealing process, the machine reduces the risk of contamination and ensures that vials are securely closed, thus preserving the quality of the contents. Additionally, modern machines often feature advanced technology, such as real-time monitoring and adjustments, which allow for consistent output and adherence to regulatory standards. This not only speeds up production but also guarantees that each vial meets the required specifications, contributing to overall operational efficiency.

Vial Filling and Sealing Machine Production Efficiency

The Importance of Vial Filling and Sealing Machines in Pharmaceuticals: Industry Insights

Vial filling and sealing machines play a critical role in the pharmaceutical industry, ensuring that liquid medications are accurately dispensed and securely sealed in vials for distribution. These machines help maintain the integrity of pharmaceutical products, minimizing contamination risks and ensuring compliance with stringent regulatory standards. As the demand for rapidly developed vaccines and medications grows, the reliance on efficient vial filling and sealing processes becomes paramount to meet industry needs.

Vial filling and sealing machines play a critical role in the pharmaceutical industry, ensuring that liquid medications are accurately dispensed and securely sealed in vials for distribution. These machines help maintain the integrity of pharmaceutical products, minimizing contamination risks and ensuring compliance with stringent regulatory standards. As the demand for rapidly developed vaccines and medications grows, the reliance on efficient vial filling and sealing processes becomes paramount to meet industry needs.

When implementing vial filling and sealing machinery, businesses should consider several essential tips. Firstly, investing in automated systems can greatly enhance productivity by reducing human error and increasing output speed. Secondly, routine maintenance of the machinery is crucial to avoid downtime and ensure consistent performance. Lastly, selecting the right type of machine for specific vial sizes and materials can significantly impact the overall efficacy and cost-effectiveness of production processes.

Understanding the importance of these machines can lead to better decision-making in equipment investment and operational practices, ultimately contributing to improved patient safety and satisfaction in the pharmaceutical sector.

Key Features and Technologies in Modern Vial Filling and Sealing Machines

Modern vial filling and sealing machines are essential in the pharmaceutical and cosmetic industries, where precision and hygiene are paramount. These machines employ advanced technologies to ensure that vials are filled accurately and sealed securely. One of the key features is the use of servo motor-driven filling heads, which provide high accuracy and can be easily adjusted for different vial sizes. This flexibility is crucial in a market that demands swift changes in production lines to meet diverse consumer needs.

Another significant technology integrated into these machines is the use of high-speed inspection systems. These systems utilize cameras and sensors to check the quality of the fill and the integrity of the seals, ensuring that no defective products reach consumers. Additionally, automated cleaning systems are often included, which minimize downtime and maintain a sterile environment essential for pharmaceutical applications. Together, these features enhance production efficiency, reduce human error, and ensure compliance with strict regulatory standards, making modern vial filling and sealing machines indispensable in today’s manufacturing landscape.

Efficiency Metrics: How Vial Filling and Sealing Machines Optimize Production Processes

Vial filling and sealing machines play a crucial role in streamlining production processes within the pharmaceutical and biotechnology industries. According to a report by Grand View Research, the global vial filling machine market size was valued at approximately $1.45 billion in 2021, with expectations to grow at a compound annual growth rate (CAGR) of 13.8% from 2022 to 2030. This growth highlights a significant trend toward automation and efficiency in production environments, where precision and speed are paramount.

Vial filling and sealing machines play a crucial role in streamlining production processes within the pharmaceutical and biotechnology industries. According to a report by Grand View Research, the global vial filling machine market size was valued at approximately $1.45 billion in 2021, with expectations to grow at a compound annual growth rate (CAGR) of 13.8% from 2022 to 2030. This growth highlights a significant trend toward automation and efficiency in production environments, where precision and speed are paramount.

Efficiency metrics are critical for assessing the performance of vial filling and sealing machines. These machines can dramatically reduce production times, with some systems capable of filling and sealing up to 300 vials per minute. Additionally, they minimize material waste by ensuring accurate fill volumes, which is essential where high-cost pharmaceutical ingredients are concerned. Data from PMMI's 2020 report indicates that companies implementing automated filling systems achieved a 25% reduction in operational costs on average, showcasing how these advanced machines not only enhance productivity but also contribute to overall cost-efficiency in manufacturing operations.

Market Trends: The Growth of Vial Filling and Sealing Machines in the Biopharmaceutical Sector

The biopharmaceutical sector has witnessed significant growth in recent years, leading to increased demand for advanced manufacturing technologies. Vial filling and sealing machines have become essential in this evolution, driving efficiency and precision in the production of sterile products. As biopharmaceutical companies expand their pipelines, these machines are increasingly adopted to meet the rigorous standards for quality and safety required in drug manufacturing, ensuring accurate filling and secure sealing of vials.

Market trends indicate a robust rise in the investment in vial filling and sealing technologies. With a focus on automation and enhanced production capabilities, manufacturers are turning to these machines to streamline processes, reduce human error, and increase output. Additionally, as regulatory requirements become more stringent, the reliability and consistency offered by modern filling and sealing systems place them at the forefront of biopharmaceutical production. This trend underscores the growing reliance on innovative technologies to achieve operational excellence in a rapidly evolving market landscape.

What is a Vial Filling and Sealing Machine and Its Role in Efficient Production

| Dimension | Value |

|---|---|

| Market Size (2023) | $2.5 Billion |

| Annual Growth Rate (CAGR) | 7.5% |

| Key Applications | Vaccines, Injectable Drugs, Biological Products |

| Technology Types | Semi-Automatic, Fully Automatic |

| Primary Markets | North America, Europe, Asia-Pacific |

| Trends | Automation, Integration with IoT, Precision Engineering |

| Challenges | Regulatory Compliance, High Initial Costs |

| Future Outlook | Increased Demand for Biologics, Enhanced Production Efficiency |

Related Posts

-

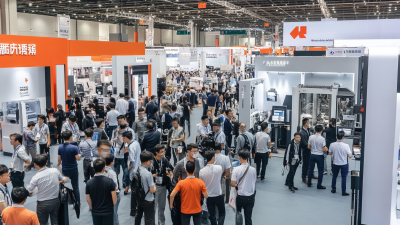

Exploring Innovations in Vial Filling and Sealing Machines at the Successful 137th Canton Fair 2025

-

A Comprehensive Comparison of the Top Vial Sealing Machines for Optimal Production Efficiency

-

The Future of Best Vial Sealing Machines Trends and Innovations Shaping the Industry

-

Unveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader

-

Revolutionizing Production with the Latest Silicone Dispensing Machine Technology and Market Insights

-

Hot Melt SondexMachinesr Machine Shines at the Record-Breaking 137th Canton Fair with Surge in International Buyers