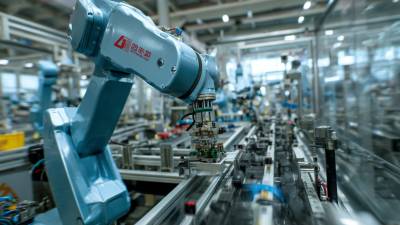

Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsMastering the Art of Robotic Filling Machine Operation for Global Buyers

As global demand for efficiency and precision in manufacturing continues to surge, the adoption of Robotic Filling Machines has become a pivotal trend in various industries, including food and beverage, pharmaceuticals, and cosmetics. According to a recent market analysis, the robotic filling machine market is projected to grow at a CAGR of over 10% from 2021 to 2026, primarily driven by increasing automation and the need for higher production rates. This technological evolution not only enhances operational efficiency but also minimizes human error, ensuring consistent product quality. For global buyers looking to invest in this innovative machinery, mastering the art of robotic filling machine operation is crucial. This blog will provide a comprehensive checklist to guide them through the essential steps and best practices for optimizing their investments and integrating these advanced systems into their production lines.

Understanding Robotic Filling Machines: Key Features and Benefits

Robotic filling machines are revolutionizing the packaging industry, offering enhanced efficiency and precision. One of the key features of these machines is their ability to automate the filling process, significantly reducing labor costs and minimizing human error. These machines are designed to handle various materials and container types, ensuring adaptability to different production needs. Their advanced sensors and control systems allow for real-time monitoring, ensuring consistent quality and reducing waste.

In addition to efficiency, robotic filling machines provide several benefits that appeal to global buyers. They enhance production speed, allowing companies to meet high demand without sacrificing quality. Furthermore, their flexibility enables manufacturers to switch between different products and container sizes with minimal downtime. This adaptability is critical in today’s fast-paced market, where responsiveness can lead to significant competitive advantages. Overall, the integration of robotic technology in filling operations not only streamlines processes but also elevates overall production standards.

Essential Skills for Effective Operation of Robotic Filling Machines

Operating robotic filling machines efficiently is crucial for global buyers aiming to enhance productivity and maintain quality in their manufacturing processes. This task requires a unique set of essential skills that go beyond basic technical knowledge. First, operators must have a solid understanding of the machinery's mechanics and software systems. Familiarity with the machine's operational parameters, troubleshooting methods, and maintenance routines ensures that any potential issues can be addressed proactively, minimizing downtime and maximizing output.

Additionally, effective communication and collaboration skills are vital in a manufacturing environment where teamwork is critical. Operators must work closely with engineers and other team members to optimize processes and implement improvements. Continuous training and staying updated with the latest technological advancements in robotic filling systems also play a significant role in operation mastery. By fostering a culture of learning and adaptability, businesses can ensure their operators are not only skilled but also equipped to handle the evolving demands of the global market.

Top Common Mistakes to Avoid When Using Robotic Filling Machines

Robotic filling machines have become essential in various industries due to their efficiency and precision. However, even seasoned operators can make common mistakes that hinder performance. One frequent error is neglecting regular maintenance. According to industry studies, proper upkeep can enhance the lifespan of equipment by up to 30%, significantly reducing downtime and costs associated with repairs.

Tip: Implement a comprehensive maintenance schedule to keep robotic filling machines running smoothly. Ensure that all components, particularly sensors and nozzles, are inspected routinely for wear and tear.

Another common pitfall is improper setup and calibration. A report by industry analysts highlights that nearly 20% of operational inefficiencies stem from incorrect machine settings. This can lead to inaccurate fills and product waste. Operators must be diligent in verifying that machines are calibrated correctly according to product specifications.

Tip: Always double-check calibration before starting a production run, and consider tracking any discrepancies to adjust future setups accordingly. By avoiding these mistakes, operators can maximize productivity and ensure top-quality filling processes, which is crucial in today’s competitive market.

How to Choose the Right Robotic Filling Machine for Your Production Needs

Choosing the right robotic filling machine is crucial for optimizing your production process and ensuring efficiency in your operations. When selecting a machine, consider the type of products you will be filling, as different machines have specific capabilities tailored for liquids, powders, or granules. Assess the container sizes and materials you will be working with, as compatibility can significantly impact your filling accuracy and speed.

**Tip 1:** Always evaluate the machine's throughput capabilities based on your production volume. A machine that can keep up with your demand will prevent bottlenecks and improve overall efficiency. Look for machines that offer adjustable speed settings to accommodate various production rates.

The level of automation your facility requires is another important factor. Fully automated machines can improve consistency and reduce labor costs, but they may require a higher initial investment. Alternatively, semi-automated systems can provide a balance between efficiency and cost.

**Tip 2:** Consider the ease of maintenance and support offered by the manufacturer. A machine that is easier to maintain will help reduce downtime and ensure smooth operation. Check for warranties and customer support options to ensure you have resources available should issues arise.

Robotic Filling Machine Production Capacity Analysis

Future Trends in Robotic Filling Technology: What Global Buyers Should Know

As robotic technology continues to advance, global buyers must stay informed about emerging trends in robotic filling machines.

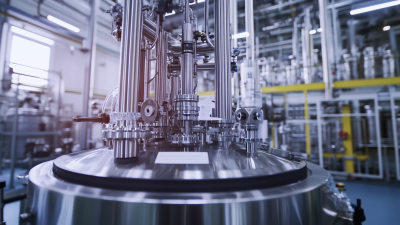

One notable trend is the increasing emphasis on smart automation. Similar to the robotic vacuum cleaner market projected to reach USD 35.56 billion by 2035, robotic filling systems are expected to evolve, enhancing efficiency and precision in production lines. Buyers should focus on selecting machines that incorporate AI algorithms enabling real-time adjustments, which can lead to optimal performance and reduced operational costs.

Another critical aspect for buyers is the proliferation of innovative capabilities within advanced industries, particularly as seen in countries like China. The nation is rapidly positioning itself as a key player in manufacturing innovation, which includes the development of sophisticated robotic filling technologies. Buyers should be proactive in understanding how advancements in artificial intelligence, machine learning, and IoT integration can transform traditional filling processes, leading to a more agile and resilient supply chain. These insights will be crucial as the market landscape shifts towards automation and sustainability in the coming years.

Related Posts

-

Unveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader

-

Comprehensive Resource on Selecting the Right Bottle Filling Machine for Your Business

-

Challenges Faced with the Best Liquid Vial Filling Machine in Modern Production

-

China's Commitment to Quality in Industrial Dispensing Equipment Driving Global Trade Success

-

The Future of Best Vial Sealing Machines Trends and Innovations Shaping the Industry

-

The Ultimate Guide to Choosing the Best Filling Capping Machine: Boost Efficiency and Sales with Data-Driven Insights