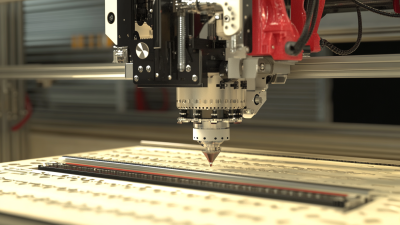

Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly Solutions5 Key Benefits of Using Sealant Dispensing Machines for Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, efficiency and precision are paramount, and one technology revolutionizing this sector is the Sealant Dispensing Machine. These advanced machines not only enhance production capabilities but also ensure consistency and quality in the application of sealants across various industries. As manufacturing demands grow increasingly complex, integrating a Sealant Dispensing Machine can streamline operations, reduce waste, and improve overall output. In this blog, we will explore the five key benefits of utilizing these machines, highlighting how they can transform manufacturing processes and contribute to a more productive and sustainable future. Join us as we delve into the advantages that make the Sealant Dispensing Machine an indispensable asset for today’s manufacturers.

Enhancing Production Efficiency: The Role of Sealant Dispensing Machines in Manufacturing

Sealant dispensing machines play a crucial role in enhancing production efficiency in modern manufacturing. By automating the application of sealants, these machines significantly reduce the time and labor costs associated with manual dispensing. This efficiency translates into faster production cycles, allowing manufacturers to meet increasing demands without compromising on quality. Furthermore, the precision offered by these machines ensures consistent application, minimizing waste and enhancing overall product reliability.

Tips to maximize the benefits of sealant dispensing machines include regular maintenance and calibration to maintain accuracy. Operators should also be trained on the best practices for loading and operating these machines to prevent delays and ensure smooth operation. Additionally, choosing the right sealant dispensing machine for your specific manufacturing needs can dramatically impact efficiency, so it’s essential to assess production requirements before making a decision. By implementing these strategies, manufacturers can fully leverage the advantages of sealant dispensing technology.

Reducing Material Waste: How Automated Dispensing Saves Costs and Resources

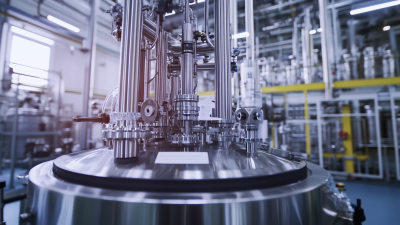

Automated sealant dispensing machines play a crucial role in modern manufacturing by significantly reducing material waste. These machines are meticulously designed to deliver precise quantities of sealant, minimizing excess and ensuring that every drop is used effectively. By optimizing the dispensing process, manufacturers can cut down on over-consumption, ultimately lowering production costs while still maintaining product quality.

Tip: Regularly calibrate and maintain your dispensing machines to ensure accuracy in every batch. This simple step can prevent costly material wastage and improve overall efficiency in your manufacturing process.

Another advantage of using automated machines is the ability to monitor material usage in real-time. This data-driven approach allows manufacturers to identify patterns and areas where waste can be further reduced. By analyzing this information, teams can implement better strategies and adjustments, resulting in not only cost savings but also enhanced sustainability practices within their operations.

Tip: Leverage software that integrates with your dispensing machines to track usage and generate reports on sealant consumption. This insight will empower you to make informed decisions that further minimize waste.

5 Key Benefits of Using Sealant Dispensing Machines for Modern Manufacturing

Improving Product Quality: The Impact of Precision Sealant Application on Manufacturing

In modern manufacturing, the precision of sealant application plays a pivotal role in enhancing product quality. Sealant dispensing machines offer unparalleled accuracy, ensuring that the correct amount of sealant is applied consistently across various surfaces. This precision minimizes the risk of over-application or under-application, both of which can lead to product failures or increased rework costs. When manufacturers invest in advanced dispensing technology, they not only optimize the production process but also significantly improve the overall durability and reliability of their products.

Moreover, the use of sealant dispensing machines facilitates better adhesion and improves multi-material bonding, which is essential in industries ranging from automotive to electronics. The controlled application method allows for intricate designs and complex assemblies without compromising on seal integrity. This advancement in manufacturing not only meets stringent industry standards but also enhances aesthetic appeal, ensuring that end products are not only functional but also visually appealing. As manufacturers strive for excellence, precision sealant application remains a critical factor in achieving superior product quality and customer satisfaction.

5 Key Benefits of Using Sealant Dispensing Machines for Modern Manufacturing

| Benefit | Description | Impact on Quality | Operational Efficiency |

|---|---|---|---|

| Increased Precision | Automated dispensing ensures accurate application of sealant, minimizing waste. | Enhances the seal integrity, leading to fewer defects. | Reduces time spent on adjustment and rework. |

| Consistency | Uniform application across products ensures consistent product quality. | Better adherence to quality standards and specifications. | Improves throughput by reducing variability. |

| Reduced Labor Costs | Less manual labor required for sealant application. | Decreases chances of human error. | Allows workforce to focus on higher value tasks. |

| Improved Product Lifespan | Proper sealant application prevents corrosion and contamination. | Longer lasting products with fewer defects over time. | Lower warranty claims and product returns. |

| Versatility | Can dispense a variety of sealants for different applications. | Meets diverse manufacturing needs without compromising quality. | Flexible manufacturing setup with reduced changeover time. |

Streamlining Labor Costs: Automating Sealant Dispensing for a Competitive Edge

In the rapidly evolving landscape of modern manufacturing, companies are constantly seeking ways to improve efficiency and reduce operational costs. One area that has shown significant potential for automation is sealant dispensing. According to a recent report by MarketsandMarkets, the global automated dispensing systems market is expected to reach $7.3 billion by 2025, growing at a CAGR of 6.9%. This trend underscores the increasing reliance on technology to enhance productivity, thereby streamlining labor costs.

Automating sealant dispensing not only minimizes manual labor but also ensures precision and consistency in application. For instance, automated systems can achieve a dispensing accuracy rate of over 99%, considerably reducing material waste and improving product quality. A study by the International Journal of Advanced Manufacturing Technology highlighted that manufacturers adopting automated sealing solutions saved up to 30% in labor costs while simultaneously boosting production rates. This competitive edge is essential in an industry where margins are often tight, and every dollar saved on labor can significantly impact the bottom line.

As manufacturers embrace sealant dispensing machines, the integration of automation will undoubtedly reshape operational strategies for the better.

Increasing Safety Standards: The Benefits of Using Dispensing Machines in Hazardous Environments

In today's manufacturing landscape, safety standards are paramount, especially in environments involving hazardous materials. The use of sealant dispensing machines significantly enhances workplace safety by reducing the risk of exposure to harmful substances. According to a 2021 report by the National Safety Council, industrial accidents involving hazardous materials account for approximately 10% of workplace injuries. By automating the dispensing process, companies can minimize direct contact with toxic materials, thereby safeguarding their workforce.

Furthermore, dispensing machines are equipped with advanced features such as automatic cut-off systems and precision control, which not only improve the quality of sealant application but also prevent accidental spills and leaks. A study conducted by the Occupational Safety and Health Administration (OSHA) noted that environments using automated dispensing systems saw a 30% reduction in hazardous incidents over three years. This automation leads to better compliance with safety regulations while promoting a culture of safety and responsibility within manufacturing operations. Enhanced training on machine operation further solidifies safety practices, ensuring that employees are well-acquainted with proper handling and emergency procedures, thereby fostering a safer working environment.

Related Posts

-

Exploring Innovative Alternatives to Best Cnc Dispensing Machines for Enhanced Efficiency

-

Global Pride in World Class Manufacturing with the Best Hot Melt Machine from China

-

Comprehensive Guide to Global Industry Standards for Best Filling Capping Machine

-

China's Commitment to Quality in Industrial Dispensing Equipment Driving Global Trade Success

-

How to Choose the Right Vial Liquid Filling Machine for Your Production Needs

-

Mastering Liquid Dispensing Equipment: A Comprehensive Guide for Global Buyers