Automated Dispensing Robot Videos

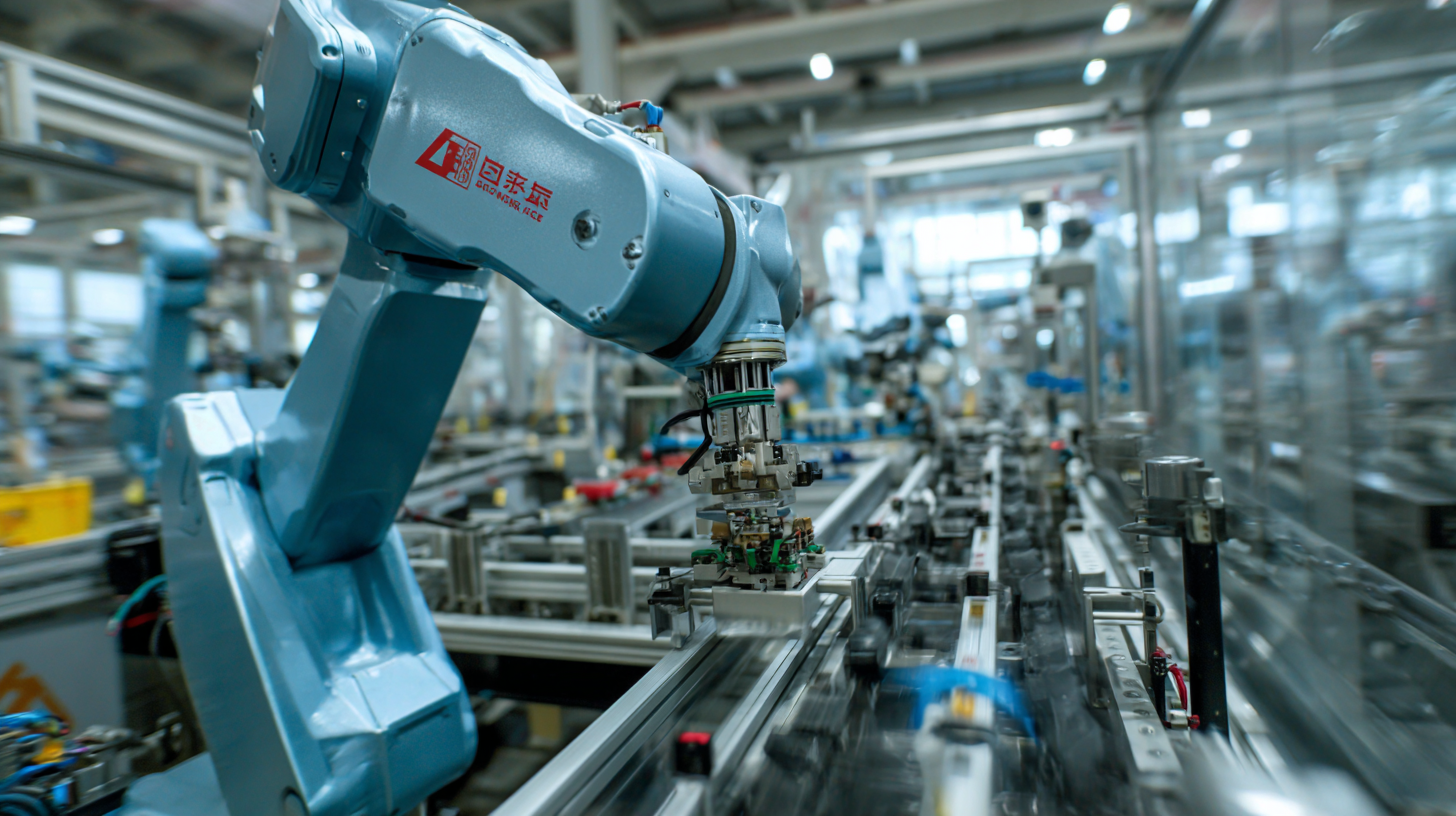

A World of Robotic Dispensing and Assembly SolutionsUnveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader

The global packaging machinery market is witnessing unprecedented growth, with the robotic filling machine segment emerging as a leader in innovation and efficiency. According to a report by MarketsandMarkets, the market for robotic filling machines is projected to reach $6.5 billion by 2025, showcasing a remarkable compound annual growth rate (CAGR) of 8.5%.

This surge is driven by advancements in automation, increasing demand for high-speed packaging solutions, and the rising need for precise filling in diverse industries.

China, as a global export leader in manufacturing, has leveraged these trends to produce some of the most advanced robotic filling machines in the market. With a strong emphasis on reliability, precision, and cost-effectiveness, Chinese manufacturers are setting new benchmarks in the industry, making their products indispensable for businesses seeking to optimize their production processes.

In this blog, we will explore the top strategies that underscore the excellence of China’s robotic filling machines and their impact on the global market.

China, as a global export leader in manufacturing, has leveraged these trends to produce some of the most advanced robotic filling machines in the market. With a strong emphasis on reliability, precision, and cost-effectiveness, Chinese manufacturers are setting new benchmarks in the industry, making their products indispensable for businesses seeking to optimize their production processes.

In this blog, we will explore the top strategies that underscore the excellence of China’s robotic filling machines and their impact on the global market.

Exploring the Key Features of China’s Top Robotic Filling Machines

China's top robotic filling machines have become synonymous with precision and efficiency, making them a cornerstone in various industries. These machines are equipped with cutting-edge technology that allows for high-speed filling with minimal human intervention. One of the key features is their adaptability; they can handle a wide range of container materials and sizes, seamlessly switching between tasks. This flexibility ensures that manufacturers can optimize their production lines without requiring extensive downtime for adjustments.

Moreover, the integration of artificial intelligence in these machines enhances their operational capabilities. Smart sensors and advanced algorithms enable real-time monitoring and quality control, significantly reducing the risk of errors and product wastage. The machines are also designed with user-friendly interfaces, simplifying the training process for new operators. With such innovations, China’s robotic filling machines not only meet the rigorous demands of domestic markets but also establish a strong foothold in global markets, cementing their reputation as leaders in engineering excellence.

Performance Comparison of China’s Leading Robotic Filling Machines

This chart illustrates the efficiency and speed of the top robotic filling machines exported from China. The data represents the average filling speed in bottles per minute across different categories: Liquid, Powder, and Granules.

The Role of Innovation in China's Robotic Filling Machine Industry

Innovation is at the heart of China's ascent in the robotic filling machine industry, positioning the country as a global export leader. The rapid advancement in robotics and automation technologies has transformed traditional manufacturing practices. Chinese firms are at the forefront, developing state-of-the-art robotic filling machines that enhance efficiency and precision. This surge is reflected in the growing demand for automated solutions across sectors, particularly in pharmaceuticals and food processing, where the need for high-quality and high-speed production is paramount.

The role of innovation is further exemplified by the emergence of sophisticated robotic systems tailored to meet the specific demands of various industries. With a substantial market projection for robot-assisted systems, China is not just improving its domestic capabilities but also setting international standards. The integration of AI and machine learning into robotics allows for smarter, more adaptive filling machines, which are essential for fostering competitiveness in the global market. As China's universities and enterprises continue to push the boundaries of research and development, the country is poised to redefine the landscape of the global robotic filling machine industry.

Global Demand for High-Quality Filling Machines: China’s Competitive Edge

The global demand for high-quality filling machines is on the rise, with the market for offset printing machines expected to reach a value of $2.683.1 million by 2025 and anticipated to grow at a compound annual growth rate (CAGR) of 1.8% to $3.094.7 million by 2033. This growth reflects the increasing need for efficient and reliable manufacturing processes across diverse industries. China's superiority in producing advanced filling machinery puts it at the forefront of this market, allowing it to cater to the global demand effectively.

Moreover, the liquid silicone rubber injection machine segment is also witnessing significant progress, driven by technology advancements in standard and high-pressure injection molding methods. The market size for these machines, essential for applications in medical equipment and consumer products, is projected to expand as industries seek to enhance production capabilities with innovative solutions. China's competitive edge in technology and manufacturing efficiency positions it as a global leader in this sector, ready to meet the increasing international demand for high-performance filling machines.

Case Studies: Successful Implementation of Chinese Robotic Filling Solutions

Exploring the successful implementation of Chinese robotic filling solutions, it becomes evident that these machines have transformed production lines across various industries. One notable case is the beverage sector, where a leading soft drink manufacturer integrated robotic filling technology to enhance efficiency. By automating the filling process, the company reduced operational costs and improved consistency in product quality, showcasing how these advanced machines can meet the demands of high-volume production.

Tips for optimizing robotic filling solutions include regular maintenance and calibration to ensure precision in operations. Investing in high-quality sensors and software can significantly enhance the machine's ability to adapt to varying product types and pack sizes. Furthermore, training staff to understand the technology will help in quick troubleshooting, ensuring minimal downtime during operations.

Another impactful case comes from the pharmaceutical industry, where a Chinese robotic filling machine was adapted for sterile environments. This innovation not only ensured compliance with stringent safety regulations but also sped up the filling process of various medications. Companies looking to implement robotic filling should consider evaluating their specific needs and choosing machines that offer customization options to suit their production requirements.

Unveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader

| Industry | Application | Production Rate (Units/Hour) | Efficiency Improvement (%) | Market Reach |

|---|---|---|---|---|

| Food and Beverage | Liquid Filling | 1200 | 30 | Asia, Europe |

| Pharmaceuticals | Vial Filling | 800 | 25 | North America, Asia |

| Chemicals | Powder Filling | 1000 | 20 | Europe, South America |

| Cosmetics | Cream Filling | 900 | 28 | Asia, Middle East |

Future Trends in Robotic Filling Technologies and China's Position in the Market

As the global market for robotic filling technologies evolves, China is positioning itself as a frontrunner in innovation and manufacturing excellence. With advancements in artificial intelligence and automation, Chinese companies are developing robotic filling systems that not only enhance efficiency but also improve precision. These state-of-the-art machines are designed to meet the diverse needs of industries ranging from food and beverages to pharmaceuticals, showcasing versatility and adaptability.

Looking to the future, trends indicate a growing demand for smart filling solutions that integrate IoT technology, allowing for real-time monitoring and data analytics. This capability optimizes production processes and minimizes waste, making robotic fillers more sustainable and cost-effective. Furthermore, as the world moves towards greater customization in product offerings, China's robotic filling machines are poised to lead the way by facilitating rapid changeovers and accommodating small batch sizes. This strategic alignment with market needs underscores China's commitment to maintaining its status as a global export leader in robotic filling technologies.