Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Right Vial Liquid Filling Machine for Your Production Needs

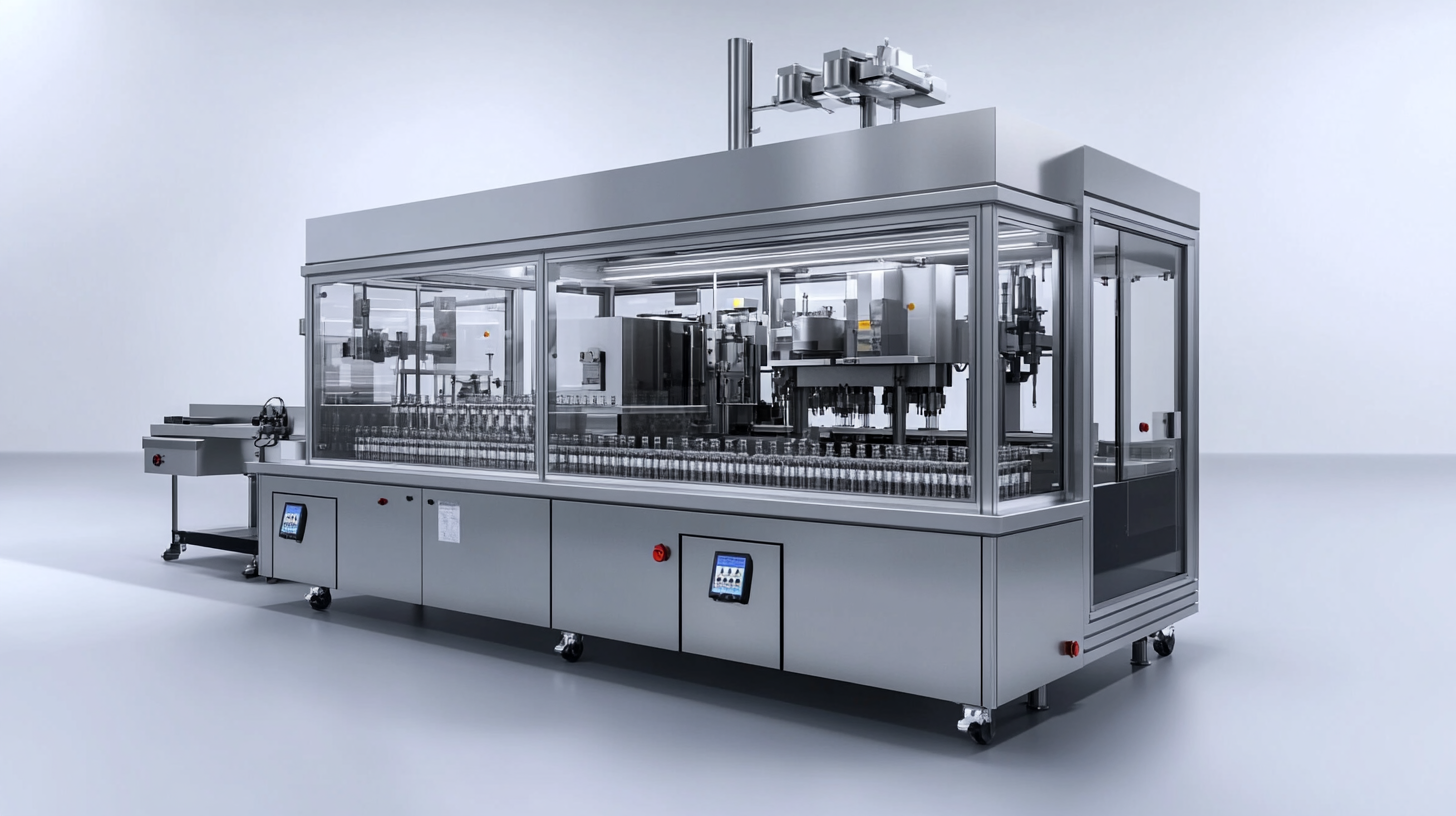

In the ever-evolving landscape of pharmaceutical and cosmetic manufacturing, selecting the right equipment is crucial for ensuring operational efficiency and product quality. One of the most vital tools in this process is the Vial Liquid Filling Machine, which plays a pivotal role in accurately filling liquid substances into vials for distribution. With a myriad of options available on the market, each varying in specifications and functionalities, it can be overwhelming for producers to determine which machine aligns best with their unique production needs. Factors such as the type of liquid being filled, production volume, and regulatory compliance must be carefully considered. This blog aims to guide you through the essential criteria for evaluating and selecting the optimal Vial Liquid Filling Machine that not only meets your requirements but also enhances your overall production capabilities.

Understanding Your Production Requirements for Liquid Filling

When choosing the right vial liquid filling machine, it’s essential to first understand your production requirements. The global liquid filling machines market is projected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 6.2%. This significant growth underscores the need for manufacturers to identify specific needs related to production volume, product viscosity, and the type of container used.

It’s important to consider the manufacturing standards and regulatory compliance, especially in the pharmaceutical sector, where stringent guidelines dictate equipment suitability. For instance, advancements such as the Romaco Macofar liquid filling machine illustrate how innovative designs can meet Good Manufacturing Practice (GMP) requirements for aseptic processes. Understanding these dynamics allows businesses to invest wisely in machinery that not only aligns with market trends but also enhances operational efficiency and product integrity.

Types of Vial Liquid Filling Machines and Their Applications

When selecting the appropriate vial liquid filling machine, understanding the various types available is crucial. There are several machine designs tailored for different applications, such as aseptic filling for pharmaceuticals, which has become increasingly important due to stringent health regulations. Reports indicate that the aseptic filling machine market is projected to reach USD 3.4 billion by 2035, reflecting a growing demand driven by innovations in pharmaceutical manufacturing processes.

Among the latest advances, modular small batch solutions are gaining traction, allowing for individual configuration based on specific production needs. These systems integrate isolators for filling aseptic and highly potent products, catering to the pharmaceutical sector's requirements for flexibility and reduced operator intervention. Additionally, high-speed machines are being introduced for filling, stoppering, and crimping vials, significantly boosting efficiency in high-demand environments.

Furthermore, the adoption of blow-fill-seal technologies is transforming the packaging landscape for pharmaceuticals, as these systems minimize contamination risks and optimize production by reducing manual handling. As the industry continues to evolve, choosing the right vial liquid filling machine involves considering factors such as the desired production speed, container type, and the level of automation required to meet market expectations effectively.

Key Features to Look for in a Vial Filling Machine

When selecting the right vial liquid filling machine for your production needs, it's crucial to focus on key features that enhance safety and efficiency. Recent innovations, such as Steriline's robotic nest filling machine showcased at Interphex 2023, emphasize the importance of integrating advanced robotic technologies to ensure high-level safety and flexibility. This shift towards automation is not just about keeping up with industry trends; it's also about meeting the growing demand, with the market for robotic vial washing and filling machines booming worldwide. According to Coherent Market Insights, the market is expected to expand significantly as businesses seek to improve their production processes.

When evaluating potential vial filling machines, consider factors such as production capacity, ease of use, and compliance with aseptic standards. For instance, machines designed with modularity can facilitate quick changeovers between different vial sizes, enhancing operational efficiency. Additionally, ensure that the filling machine is equipped with precise dosing control to minimize waste and ensure product consistency.

Tip: Perform a thorough assessment of your operational needs versus the machine's capabilities to ensure alignment with your production goals. Be mindful of after-sales support and maintenance services, as these can significantly impact the longevity and effectiveness of your equipment.

Evaluating the Efficiency and Speed of Filling Machines

When selecting the right vial liquid filling machine for production needs, evaluating the efficiency and speed of filling machines is paramount. Recent industry reports indicate that automated filling systems can achieve filling speeds of up to 300 vials per minute, significantly reducing operational bottlenecks. This increase in speed not only enhances throughput but also minimizes labor costs associated with manual filling processes. By adopting high-speed machines, companies can meet the growing demand for faster turnaround times without sacrificing product quality.

Moreover, efficiency in liquid filling machinery is a critical factor, especially when considering energy consumption and resource utilization. Studies show that efficient filling machines can reduce energy use by up to 30%, contributing to overall sustainability efforts in manufacturing. This is particularly relevant in sectors such as pharmaceuticals and cosmetics, where precision is essential. As production scales, investing in machines that optimize both speed and energy efficiency can lead to substantial savings and improved competitiveness in the market. Understanding these metrics will assist businesses in making informed decisions that align with their production goals.

Efficiency and Speed of Vial Liquid Filling Machines

This bar chart illustrates the efficiency and speed of different types of vial liquid filling machines, focusing on their average filling speed (in vials per minute) and overall efficiency percentage.

Budgeting for Your Vial Liquid Filling Machine Purchase

When budgeting for a vial liquid filling machine, it's essential to consider not just the upfront cost, but also the long-term operational efficacy. A well-planned budget should include expenses related to maintenance, efficiency upgrades, and potential downtime costs. Companies can benefit from adopting a Machinery-as-a-Service (MaaS) model, which allows for reduced capital expenditure while ensuring that the machinery is maintained and optimized by the supplier. This innovative approach aligns the interests of both the brand owners and suppliers, creating a shared financial responsibility that can significantly enhance the overall productivity.

Investing wisely in a vial liquid filling machine means understanding the specific requirements of your production line. Identify what features are crucial for your operations, such as speed or versatility. While cheaper machines may seem appealing, they can lead to higher costs down the line due to inefficiencies or breakdowns. Balancing quality with budget constraints is paramount, making it vital to research and possibly engage in trial periods before committing to a purchase. Remember, a thoughtful investment can lead to significant cost savings in the future.

| How to Choose the Right Vial Liquid Filling Machine for Your Production Needs - Budgeting for Your Vial Liquid Filling Machine Purchase | ||||

|---|---|---|---|---|

| Criteria | Description | Cost Range (USD) | Production Capacity (vials/hour) | Recommended Brands |

| Machine Type | Automatic, Semi-Automatic, Manual | $5,000 - $100,000 | 500 - 3,000 | Brand A, Brand B |

| Filling Volume | 0.5ml to 100ml | $10,000 - $50,000 | 300 - 1,500 | Brand C, Brand D |

| Automation Level | Fully Automatic vs. Manual | $8,000 - $80,000 | 600 - 2,500 | Brand E, Brand F |

| Maintenance | Ease of maintenance and service | $1,000 - $5,000 (annual) | N/A | Brand G, Brand H |

| Additional Features | Integrated inspection systems, software | $2,000 - $20,000 | N/A | Brand I, Brand J |