Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Right Motorized Valve for Your System?

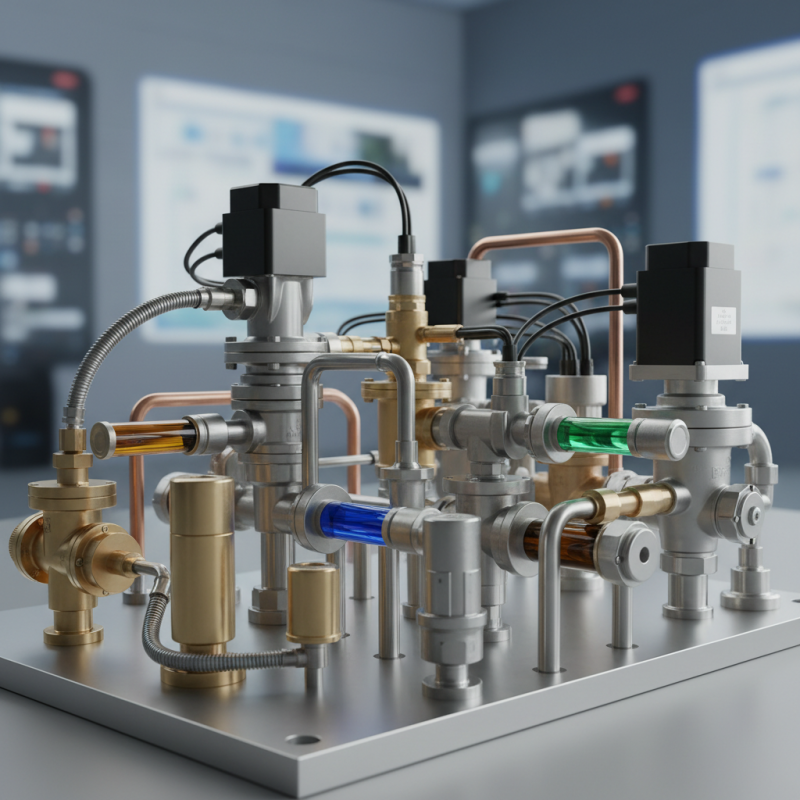

Choosing the right Motorized Valve is crucial for efficient system performance. Many factors come into play, from size to flow rate. A motorized valve is not just any valve; it plays a pivotal role in controlling fluid flow.

Understanding the specific requirements of your system is essential. Different applications demand different features. For instance, some systems need quick response times. Others prioritize durability and reliability. The materials used in the valve can affect its longevity and effectiveness.

Consider the installation environment as well. Will the valve be exposed to harsh conditions? If so, it needs to withstand temperature and pressure variations. Take time to reflect on these aspects. Making a hasty choice could lead to inefficiencies and costly repairs. A well-thought-out decision will save you headaches in the long run.

Understanding the Functionality of Motorized Valves in Fluid Systems

Motorized valves play a critical role in fluid systems, controlling flow rates and pressure with precision. These valves are essential in industries such as water treatment, HVAC, and chemical processing. According to a report from MarketsandMarkets, the global market for motorized valves is expected to reach $7 billion by 2025, reflecting their increasing importance.

Understanding the functionality of motorized valves is crucial for system efficiency. These devices use an electric motor to open or close the valve, ensuring timely response to system demands. When implemented correctly, they minimize energy waste and enhance system performance. Surprisingly, many systems still operate with outdated manual valves, leading to inefficiencies. In fact, studies show that retrofitting with motorized valves can improve energy usage by up to 30%.

However, selection is not always straightforward. Factors like flow rate, pressure requirements, and environmental conditions must be considered. A mismatched valve can cause issues such as overshooting control parameters or excessive wear. Inevitably, understanding these complexities gets overlooked. It requires careful analysis and sometimes a trial-and-error approach to find the perfect match for specific applications. The intricacies of motorized valve systems demand attention and reflection on existing practices.

Key Factors to Consider When Selecting a Motorized Valve

When selecting a motorized valve for your system, consider several crucial factors. The valve type must match the application requirements. For instance, if you need precise flow control, a globe valve may be more suitable than a ball valve. Material selection is vital. Corrosive environments require durable materials that can withstand harsh conditions. Failure to choose properly can lead to frequent replacements and increased costs.

Actuator specifications also play a significant role. Match the actuator torque and speed to your system's demands. Consider the power source; whether it’s AC or DC can affect your overall efficiency. Don’t overlook the size and dimensions of the valve. An ill-fitting valve can cause pressure drops and operational inefficiencies.

Installation is another factor that should not be rushed. Take time to follow best practices to avoid costly mistakes. Inadequate installation can result in leaks and system failures. It's crucial to assess your specific system needs and the environment in which the valve will operate. This reflection can lead to a well-informed decision. Remember, even small oversights can lead to significant challenges down the line.

Different Types of Motorized Valves and Their Applications

When selecting a motorized valve, understanding the different types available is crucial. There are several common types: globe valves, ball valves, and butterfly valves. Globe valves are fantastic for precise flow control. They are ideal for throttling applications. Ball valves, on the other hand, offer quick shut-off. They are better for full-flow applications. Butterfly valves are lightweight and space-efficient, making them suitable for large volume flows.

Applications vary significantly across industries. In HVAC systems, motorized valves regulate heating and cooling. In water treatment, they control flow rates effectively. But, not all valves suit every situation. Misalignment can lead to inefficiencies. A poorly chosen valve may result in leaks or excessive pressure drops.

Evaluating Compatibility with Existing System Components

When selecting a motorized valve, compatibility is crucial. Many systems use components that must work together seamlessly. A valve may perform excellently alone but fail when integrated into an existing system. Research shows that around 30% of system failures are linked to component incompatibility. This statistic highlights the importance of thorough evaluation.

Understanding your current system's specifics helps in making informed choices. Consider pipe sizes, flow rates, and pressure levels. A mismatch here can lead to inefficiencies or even damage. For example, a valve rated for higher pressure might not function well in a system that operates at lower levels. Experts recommend verifying specifications against manufacturer data. Aim for a match that optimizes performance and enhances longevity.

Finally, don't overlook control signal types. Different systems use various signals to operate valves—electrical, pneumatic, or hydraulic. Misalignment here can lead to operational hiccups. Some systems struggle with automated controls if the valve does not have the required features. Be diligent in assessing all aspects. This attention to detail can vastly improve system reliability and effectiveness.

Assessing Control Options for Motorized Valves in Automation

When choosing motorized valves for your automation system, control options matter significantly. Different applications demand varied control strategies. Simple on/off control may suffice for basic tasks, while complex processes often require precise modulation. You need to assess your system's needs carefully.

Actuator types can vary widely. Electric, pneumatic, and hydraulic actuators each come with unique advantages. For example, electric valves are typically easier to integrate into existing systems. But they may lack the speed needed for some operations. Pneumatic solutions provide rapid responses but require compressed air, adding complexity. Balancing these factors is crucial.

Consider the environment, too. Dust, moisture, and temperature extremes can affect valve performance. Some may thrive in harsh conditions, while others may falter. Each control option must align with your specific operational context. Testing under real conditions is recommended. It can reveal unforeseen challenges. Not every solution will fit perfectly. Adapting to changing needs is essential for long-term performance.