Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Best Hot Melt SondexMachinesr Machine for Your Production Needs

In today's fast-paced manufacturing landscape, selecting the right Hot Melt SondexMachinesr Machine is crucial for optimizing production efficiency and product quality. According to recent industry reports, the global hot melt adhesives market is anticipated to reach USD 7.82 billion by 2026, growing at a CAGR of 5.9% from 2021 to 2026. This growth underscores the increasing demand for reliable and efficient dispensing technologies across various sectors, including automotive, packaging, and woodworking. As businesses strive to enhance their operational capabilities, understanding the specific requirements of their production lines becomes more critical than ever. A well-chosen hot melt dispenser not only improves adhesion processes but also significantly reduces material waste and operational costs. In this blog, we'll explore key factors to consider when selecting a hot melt dispenser that aligns with your unique production needs, ensuring that your manufacturing processes remain competitive and efficient in the dynamic global market.

Factors to Consider When Selecting a Hot Melt SondexMachinesr Machine for Production

When selecting a hot melt dispenser machine for production, several critical factors must be taken into account. Firstly, understanding the specific production needs, such as the types of materials used and the required application temperatures, is essential. According to the latest analysis on the medical injection molding machine market, various machine configurations can influence production efficiency. Manufacturers should consider hydraulic versus electric systems, as each presents distinct advantages based on the type of adhesive application and output speed needed.

Another vital aspect is the temperature stability of the machine. Consistent temperature control directly affects the dispensing quality and ultimately the final product's performance. For example, in the food industry, where safety and precision are paramount, adhering to stringent production standards is crucial. A recent survey among industry professionals indicated that machines featuring advanced temperature monitoring systems significantly reduce defect rates. Therefore, when investing in a hot melt dispenser, it is advisable to prioritize models that offer reliable temperature management to ensure optimal production outcomes.

Understanding Different Types of Hot Melt SondexMachinesr Machines and Their Applications

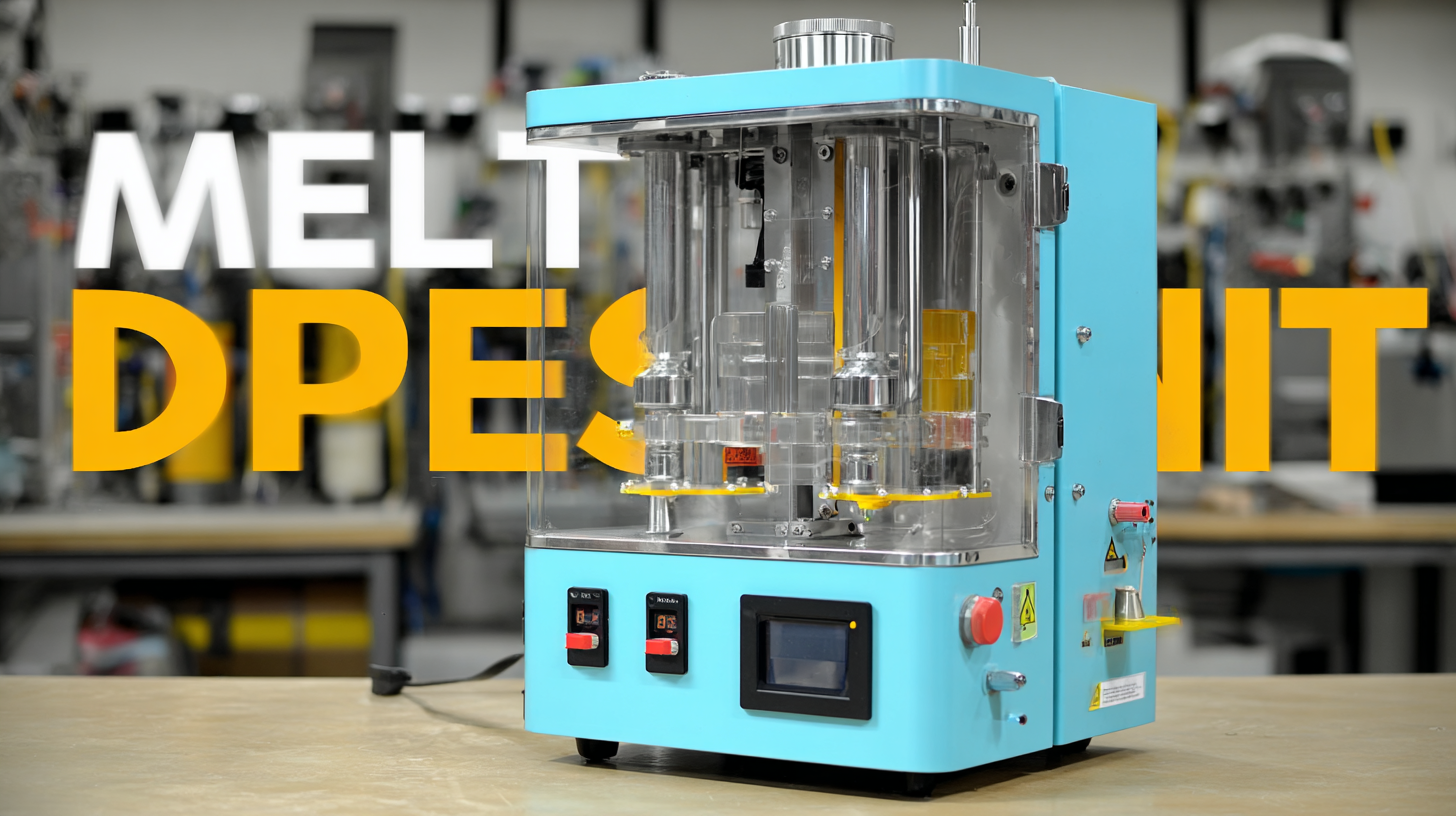

When selecting a hot melt dispenser machine for your production needs, it's crucial to understand the various types available and their specific applications. Hot melt dispensers come in several varieties, including handheld, stationary, and automated models. Handheld dispensers are ideal for smaller tasks and projects requiring mobility, while stationary dispensers are suited for high-volume production, providing consistent and efficient adhesive application. Automated systems, on the other hand, are designed for large-scale operations, integrating seamlessly into assembly lines to enhance productivity.

Tips: Always consider your production rate and the viscosity of the adhesive when choosing a hot melt dispenser. A dispenser with adjustable temperature settings can accommodate different adhesive types, ensuring optimal performance. Additionally, check for compatibility with existing equipment to avoid costly upgrades or modifications.

Another vital aspect to evaluate is the ease of maintenance and operation of the machine. Some designs offer user-friendly controls and quick-change capabilities, reducing downtime during production. Ensure that the machine's build quality is robust enough to handle your specific environmental conditions, particularly if you operate in a high-speed or demanding setting.

Evaluating Performance Metrics: Speed, Precision, and Efficiency in Hot Melt SondexMachinesrs

When selecting a hot melt dispenser machine, evaluating its performance metrics—speed, precision, and efficiency—is crucial to meeting your production demands. Speed is especially important in high-volume environments; a machine that can dispense adhesive quickly without compromising on quality can significantly enhance throughput. Look for dispensers that offer adjustable speed settings to accommodate different production line requirements while maintaining a consistent output.

Precision is another fundamental aspect to consider. A high-quality hot melt dispenser should provide accurate adhesive placement, minimizing waste and ensuring a strong bond. Machines with advanced technology, such as servo-driven systems or fine-tuning capabilities, can deliver the exact amount of adhesive needed for various applications, thereby optimizing material usage. Finally, efficiency encompasses both the machine’s energy consumption and its operational uptime. SondexMachinesrs designed with energy-saving features not only reduce operational costs but also contribute to a more sustainable production process. By focusing on these performance metrics, you can select a hot melt dispenser that enhances both productivity and quality in your manufacturing operations.

The Importance of Quality and Reliability in Hot Melt SondexMachinesr Manufacturing

When selecting a hot melt dispenser machine, quality and reliability stand out as crucial factors that can significantly impact production efficiency and product integrity. A high-quality machine not only ensures consistent application of adhesives but also minimizes downtime due to malfunctions. This aspect is particularly important in industries where precision bonding is essential, such as packaging, automotive, and electronics. Investing in a reliable hot melt dispenser can ultimately reduce operational costs by preventing wastage and the need for frequent repairs.

Moreover, the construction and design of the hot melt dispenser play a pivotal role in its performance. Machines built with durable materials and advanced technology are less likely to encounter issues under stress. Additionally, user feedback and industry reputation can provide insights into the reliability of the equipment. Companies should prioritize sourcing machines from reputable manufacturers known for their commitment to high standards. This approach not only enhances production capability but also ensures that the adhesive application process aligns with industry regulations and safety standards, contributing to the overall success of manufacturing operations.

How to Choose the Best Hot Melt SondexMachinesr Machine for Your Production Needs

| Feature | Description | Importance |

|---|---|---|

| Temperature Control | Precise temperature management for optimal adhesive application. | Ensures consistent bond quality and prevents overheating. |

| SondexMachinesr Speed | Rate at which adhesive is dispensed. | Affects production efficiency and cycle times. |

| Nozzle Size | Size of the nozzle through which the adhesive is applied. | Influences the flow rate and precision of application. |

| Ease of Maintenance | Convenience of cleaning and servicing the machine. | Reduces downtime and prolongs the life of the equipment. |

| Material Compatibility | Types of adhesives and substrates the machine can work with. | Ensures versatility for various production needs. |

| User Interface | Design of controls and displays for machine operation. | Affects operator efficiency and training time. |

| Safety Features | Inbuilt safety mechanisms to protect operators. | Essential for minimizing risks during operation. |

Cost-Effectiveness and Return on Investment for Hot Melt SondexMachinesr Machines

When selecting a hot melt dispenser machine, understanding cost-effectiveness and return on investment (ROI) is crucial for any production facility. Investing in a high-quality hot melt dispenser can lead to significant long-term savings. Firstly, these machines improve adhesive application efficiency, reducing material wastage and labor costs. Choosing a model that matches your production volume and complexity can streamline operations, minimizing downtime and boosting output.

Moreover, evaluating ROI involves not only the initial purchase price but also the machine's durability and maintenance costs. Reliable machines with minimal breakdowns contribute to seamless production, directly impacting profitability. Additionally, consider how advanced features, such as precise temperature control and automated dispensing, can enhance product quality. These factors can ultimately lead to increased customer satisfaction and repeat business, making the investment in a superior hot melt dispenser pivotal for your production needs.