Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsEssential Checklist for Choosing the Right Sealant Dispensing Machine

In the rapidly evolving landscape of manufacturing and construction, the significance of a reliable Sealant Dispensing Machine cannot be overstated. According to a report from MarketsandMarkets, the global sealant market is projected to reach USD 12.20 billion by 2026, growing at a CAGR of 4.8% during the forecast period. This growth is heavily reliant on advancements in dispensing technologies, as businesses seek to enhance efficiency and precision in their applications. The right sealant dispensing machine can greatly impact product quality, reduce waste, and optimize production workflows, making the selection process crucial for companies aiming to stay competitive. Therefore, understanding the essential features and considerations when choosing a sealant dispensing machine is imperative for any organization looking to leverage the full potential of modern sealing solutions.

Key Features to Consider When Selecting a Sealant Dispensing Machine

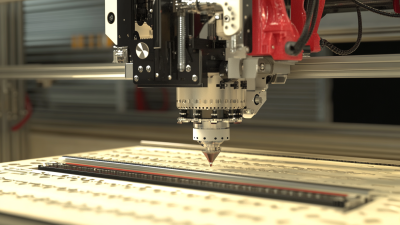

When selecting a sealant dispensing machine, understanding the key features that will best suit your application is crucial. A top consideration is the machine's compatibility with both one-part and two-part materials, as this flexibility can significantly enhance production efficiency. New advancements in bench-top dispensing robots have made it easier to handle a variety of adhesive, sealant, and gasketing applications, allowing for precision and consistency in your projects.

Another critical feature to evaluate is the machine’s ease of use and the automation capabilities it offers. A system that integrates seamlessly into your existing workflow can save time and reduce labor costs. Moreover, look for machines that come with a comprehensive turn-key robotic dispensing system, as these setups can simplify the installation and training process, enabling your team to hit the ground running.

Tips: Always assess the maintenance requirements of the dispensing machine to ensure you can keep it in top condition. Additionally, consider the availability of customer support and spare parts, as this can prevent costly downtime. Lastly, reading reviews and case studies can provide insights into the machine's performance in real-world scenarios, helping you make an informed decision.

Understanding Different Types of Sealant Dispensing Technologies

When selecting the right sealant dispensing machine, understanding the different types of dispensing technologies is crucial. Each technology offers distinct advantages tailored to specific applications. For instance, pneumatic dispensing machines utilize air pressure to dispense sealants consistently, making them ideal for high-speed production environments. Their ability to control flow rates accurately ensures minimal waste, translating to cost efficiency in large-scale operations.

On the other hand, electronic or robotic dispensing systems have gained traction for their precision and automation capabilities. These machines are equipped with advanced sensors and software, allowing for programmable dispensing patterns that enhance repeatability and accuracy. This technology is particularly beneficial in industries requiring intricate sealing applications, such as automotive or aerospace, where precision is paramount. Additionally, manual or handheld dispensers remain a practical choice for smaller projects or repairs, providing flexibility and ease of use without compromising on performance. Each type of sealant dispensing machine offers unique benefits, making an informed choice essential for successful outcomes in sealant application.

Evaluating Production Capabilities and Output Requirements

When evaluating production capabilities and output requirements for sealant dispensing machines, it's crucial to consider the specific needs of your manufacturing process. The machine's production capacity should align with your operational goals, whether you're producing for a high-volume assembly line or a more specialized output. An assessment of both current and future needs will help in selecting a machine that not only meets present demands but can also scale with your growth.

Tip: Conduct a thorough analysis of your production rates and expected increases in demand over time. This will guide you in choosing a sealant dispensing machine that offers flexibility and scalability in its output capabilities.

Furthermore, take into account the machine's compatibility with various sealant types and its efficiency in reducing waste. An efficient output means lower costs and a more sustainable operation—a key consideration in today’s environmentally conscious manufacturing landscape.

Tip: Research the machine's technical specifications, including output rates in relation to different materials, to ensure optimal performance. A machine that balances throughput with precision will enhance your overall production efficiency.

Assessing Maintenance and Support for Your Sealant Dispensing Machine

When selecting a sealant dispensing machine, assessing its maintenance and support is crucial to ensuring long-term efficiency and productivity. According to the 2022 Industry Analysis Report on Sealant Technologies, businesses that prioritize machine maintenance can extend equipment life by up to 30%, significantly reducing downtime and costly repairs. Consequently, it's vital to understand the maintenance protocols offered by manufacturers, including the availability of replacement parts and trained support staff who can provide timely assistance.

Tip: When evaluating potential machines, inquire about the manufacturer's maintenance schedule and the type of training available for your team. A well-documented maintenance schedule will help you anticipate servicing needs, while effective training can empower your staff to address minor issues independently.

Moreover, consider the support resources available, such as manuals, tutorials, and customer service access. Reports indicate that companies with robust support systems experience 15% less operational disruption compared to those without. Ensuring easy access to knowledgeable support can save your operation time and money.

Tip: Choose machines with comprehensive online resources and responsive customer service, as these factors are critical to minimizing downtime and maximizing productivity. Always request feedback from current customers regarding their experiences with maintenance and support, as real-world insights can guide your decision.

Budgeting: Cost Considerations for Sealant Dispensing Machines

When selecting a sealant dispensing machine, budgeting is a critical factor that demands careful consideration. The costs associated with these machines can vary widely based on their complexity, capacity, and the technology used. For small businesses or startups, it’s crucial to assess not only the purchase price but also the long-term operational costs, including maintenance, parts replacement, and annual servicing. Investing in a higher quality machine may come with a steeper initial cost, but it can lead to greater reliability and efficiency, ultimately saving money over time.

Moreover, consider any additional costs related to training staff to use the new equipment effectively. A machine that is user-friendly may require less training, which can help to minimize downtime and reduce training expenses. It's also important to factor in potential upgrades or modifications that may be required as production needs evolve. By laying out a comprehensive budget that includes all associated costs, businesses can make informed decisions and choose a sealant dispensing machine that aligns with their financial capabilities while meeting their operational requirements.

Related Posts

-

Exploring Innovative Alternatives to Best Cnc Dispensing Machines for Enhanced Efficiency

-

Top Strategies for Maximizing Efficiency with Silicone Dispensing Machines

-

Unlocking Precision: The Best Industrial Dispensing Equipment Specifications You Need to Know

-

Future Market Trends for Best Vial Liquid Filling Machines by 2025 and How to Choose the Right One

-

Challenges Faced with the Best Liquid Vial Filling Machine in Modern Production

-

Ultimate Guide to Best Glue SondexMachinesr Machine Price Specifications and Operation Tutorial