Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsWhat is a Ball Bearing and How Does it Work?

Ball Bearings are crucial components in machinery, affecting performance and durability. According to industry reports, the global ball bearing market is projected to reach $18.8 billion by 2026, growing at a CAGR of 5.2%. This growth highlights the significance of ball bearings in various applications, from automotive to aerospace.

Understanding how ball bearings work is essential for optimizing mechanical systems. They reduce friction between moving parts, leading to smoother operations and longer lifespans. A ball bearing typically consists of an outer race, inner race, and balls that facilitate motion. However, improper installation or low-quality materials can lead to failures.

Despite advancements in technology, the ball bearing industry grapples with challenges. Some manufacturers prioritize speed over quality. This often results in unreliable products that can cause costly breakdowns. Therefore, a balanced approach to manufacturing and quality control is vital in this competitive market.

What is a Ball Bearing: Definition and Basic Functionality

A ball bearing is a crucial mechanical component. It helps reduce friction between moving parts. By enabling smooth rotation, it enhances the performance of machines. The primary role of a ball bearing is to support loads and facilitate rotary motion. This simple device consists of balls encased between two rings, known as races.

According to a report by MarketsandMarkets, the global bearing market is projected to reach $132.5 billion by 2025. This growth reflects the increasing demand for high-performance bearings in various sectors, such as automotive and aerospace. Ball bearings play a pivotal role in this trend. They improve efficiency, contributing to energy savings.

However, challenges exist in ball bearing design. For instance, ensuring proper alignment can be tricky. Misalignment often leads to premature wear. Additionally, environmental factors can impact their lifespan. Regular maintenance is essential. It helps mitigate wear and tear, ensuring long-term reliability. These concerns highlight the need for continual innovation in bearing technology.

The Components of a Ball Bearing: An Overview

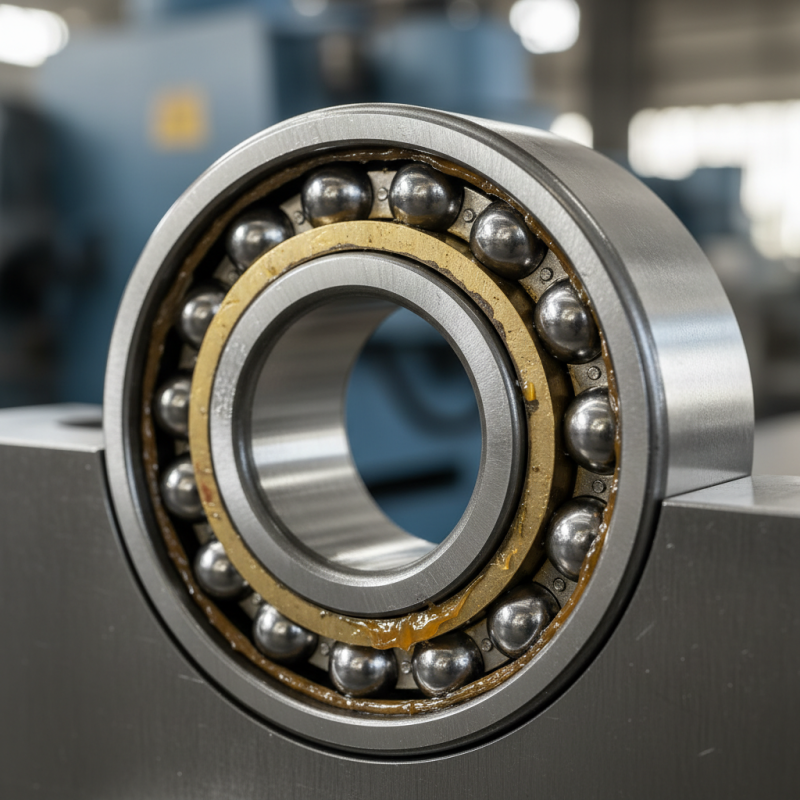

Ball bearings are essential components in many machines. They allow smooth movement and reduce friction. At the core of a ball bearing are several key components: an outer race, an inner race, balls, and a cage. The outer race serves as the stationary part. This is where the bearing is mounted. The inner race rotates, providing a surface for the balls to glide on. The balls are usually made of steel or ceramic, and they reduce friction between the races.

The cage is a critical element, holding the balls in place. It ensures they remain evenly spaced. This spacing is vital to maintain balance. When a ball bearing spins, the balls roll between the inner and outer races. This rolling motion minimizes contact and heat buildup. Still, sometimes, improper installation can lead to uneven wear. Regular inspection is essential to prevent premature failure.

**Tip:** When installing ball bearings, ensure proper alignment. Misalignment can cause damage over time. Replace any worn-out components immediately. Keep the bearing lubricated for optimal performance.

Some manufacturers offer sealed bearings. These help retain lubricant and keep contaminants out. However, sealed bearings may complicate repairs. Consider all options before making a choice. Each type has its advantages and drawbacks.

How Ball Bearings Reduce Friction and Improve Efficiency

Ball bearings play a crucial role in reducing friction in various machinery. They consist of small balls held within a metal or plastic ring. This design allows for smooth rotation or linear movement. According to industry reports, effective ball bearings can decrease friction by up to 90%. This significantly improves machine efficiency, leading to better performance and energy savings.

The reduction in friction is vital. Less friction means less heat generated. Consequently, machines require less energy to operate. A report from the Journal of Manufacturing Science reveals that using high-quality ball bearings can enhance the lifespan of machinery by over 30%. Still, not all bearings achieve these standards. Some are prone to wear, leading to increased friction and maintenance issues. Users often overlook these factors, focusing solely on the initial cost rather than long-term savings.

Moreover, the materials used in ball bearings impact their efficiency. Steel bearings are common but can rust over time. Ceramic or hybrid balls may offer better resistance, yet they come with a higher price tag. It’s essential to evaluate the requirements carefully. Balancing costs and performance is not always straightforward, and mistakes can lead to suboptimal results.

Different Types of Ball Bearings and Their Applications

Ball bearings come in various types, each designed for specific applications. The most common types include deep groove, angular contact, and self-aligning bearings. Deep groove ball bearings are versatile and can handle both radial and axial loads. They are widely used in electric motors, automotive applications, and household appliances. Their simple design makes them easy to maintain, but they can wear out over time if not properly lubricated.

Angular contact bearings excel in taking high axial loads combined with radial loads. They are commonly found in machinery and aerospace applications. However, improper installation can lead to premature failure. Self-aligning ball bearings are unique as they can tolerate misalignment. They are often used in applications where shaft alignment can be a challenge, like in conveyor systems. Still, these bearings may exhibit lower load capacity compared to other types, so their application must be carefully considered. Each type of ball bearing has its advantages and challenges, highlighting the importance of understanding their specific needs in real-world applications.

What is a Ball Bearing and How Does it Work? - Different Types of Ball Bearings and Their Applications

| Type of Ball Bearing | Description | Applications | Load Capacity |

|---|---|---|---|

| Deep Groove Ball Bearing | Common type, suitable for high speeds and radial loads | Electric motors, household appliances | Up to 1,500 kg |

| Angular Contact Ball Bearing | Designed to handle both axial and radial loads | Pumps, machine tools | Up to 2,000 kg |

| Self-Aligning Ball Bearing | Allows for misalignment due to shaft displacement | Agricultural machinery, automotive applications | Up to 1,800 kg |

| Thrust Ball Bearing | Handles axial loads in one direction | Gearboxes, automotive clutches | Up to 900 kg |

| Miniature Ball Bearing | Designed for small applications with limited space | RC vehicles, watches, instruments | Up to 100 kg |

The Manufacturing Process of Ball Bearings: Materials and Techniques

Ball bearings play a critical role in many mechanical systems. The manufacturing process of these essential components involves several key techniques and materials. Steel and ceramic are commonly used. Steel is favored for its strength. Ceramic is lightweight and offers low friction.

The manufacturing process begins with the selection of raw materials. High-quality steel is often chosen for its durability. The next step involves forging the balls into precise shapes. This can be done using various methods, including hot forging or cold heading. After forming, the balls are heat treated to enhance their properties and hardness.

However, not all production processes are perfect. There can be issues with tolerances, affecting performance. For example, poorly sized balls can lead to increased friction. Improperly hardened materials may also wear out quickly. It's important for manufacturers to continuously assess and refine their techniques for better quality control. This reflection is crucial for improving overall product reliability.

Ball Bearing Materials and Production Techniques

This chart demonstrates the composition of different materials used in the manufacturing of ball bearings. Steel is the most commonly used material, accounting for 60% of ball bearings produced, followed by ceramic at 20%, and plastic, bronze, and copper making up the remainder.